Dell’s new prototype laptop shows how easy it could be to repair and r

A lot of electronics aren’t designed for recycling or repair—I’m creating this on an outdated MacBook Pro with proprietary screws that make it tricky to open up, and inside, the battery is glued to the situation and blocking far more screws required to entry other pieces. But manufacturers are commencing to rethink their patterns to make it achievable to increase the longevity of their goods instead of just throwing them out when a single element breaks. In a new proof-of-strategy, Dell exhibits how a laptop computer can be optimized for the round economic system.

“We’re by now seeking at how we fix and refurbish our products and solutions,” says Drew Tosh, design and style advancement supervisor at Dell, which aims to redesign all of its items for circularity by the conclude of the 10 years. “But seriously, as we begun bringing up this concept of ‘design for harvest,’ in which we can, in essence, very easily disassemble and declare back [parts] . . . the next lifestyle of products was form of the critical tenet.”

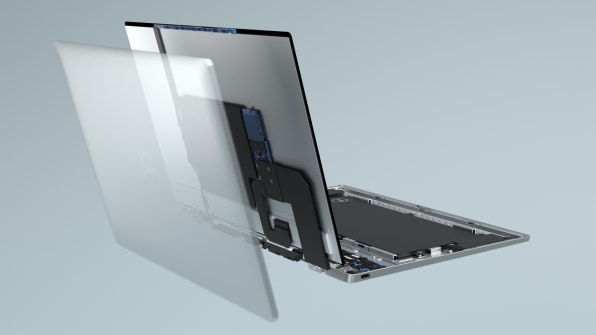

The prototype design and style, identified as Thought Luna, starts off by lessening the dimension and variety of factors that are desired. The exhibit has much less levels. The motherboard, 1 of the components of a personal computer that can take the most electricity to manufacture, is 75{18fa003f91e59da06650ea58ab756635467abbb80a253ef708fe12b10efb8add} smaller, with less areas. As the designers brainstormed how to enhance the computer’s admirer, they understood that they could get rid of the need for it totally: By going the little motherboard from the base of the laptop to the display, it is uncovered to more air, and can remain cool without the need of a enthusiast. The a lot more economical layout also indicates that it demands a scaled-down battery, and ought to last 2 times as very long, so it can afterwards be reused. All of the modifications assist slash the product’s carbon footprint roughly in fifty percent.

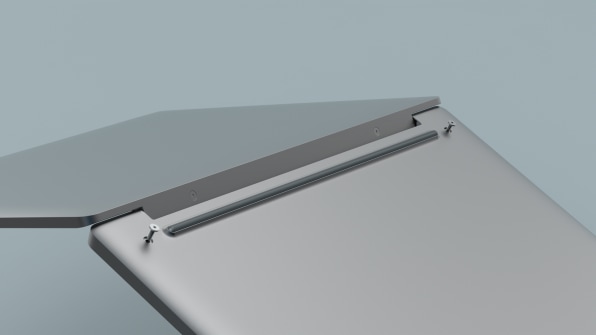

When an interior section demands a restore or the laptop or computer eventually desires to be recycled, anything can effortlessly be taken apart. Accessing the inside demands eradicating just 4 screws, 10 periods fewer than a comparable product or service. Just two screws hold up the screen. Tosh compares the design to the keystones made use of in architecture, stones at the prime of an arch that hold the rest alongside one another. The most important assemblies of the exhibit and the keyboard “lock every little thing into place,” he suggests. “And so with just two screws, we get all the fixing that we need to have, as an alternative of adding 50 or so numerous screws to hold every thing alongside one another in a sturdy way.” The keyboard conveniently pops out, if just the keyboard necessitates correcting (an issue that has plagued some new Apple laptops).

For the providers that Dell associates with to refurbish computers, it could indicate conserving an hour and a 50 {18fa003f91e59da06650ea58ab756635467abbb80a253ef708fe12b10efb8add} on disassembly time, and saving money. It also usually means that if one particular portion breaks and the rest of the solution has a lot more lifestyle, prospects could much more simply make repairs by themselves. “We try out to incentivize that,” Tosh suggests. “We’re making it so uncomplicated. We’re likely to send you parts—it will consider 10 minutes to acquire the screws out, take away the keystone, and set back your keyboard. . . . So they will be significantly a lot more probable to continue to keep working with that merchandise in its place of on the lookout for a new one.” (Apple not long ago reversed a lengthy-standing situation towards repairability, letting Iphone house owners to make some repairs on their own with out voiding their warranties.)

The style and design consists of other innovations, this kind of as a printed circuit board that is created with plant-based mostly fiber in its place of plastic and makes use of drinking water-soluble glue. When recyclers area the board in water, it can dissolve so they can quickly access the important metals on the board.

Dell is not probably to deliver this distinct solution to market. But as it checks the prototypes that it built, the workforce will decide which attributes can transfer forward on new products. The reducing-edge motherboard, Tosh claims, will choose much more time, but the “keystone” structure with much less screws could be executed swiftly. Other design and style teams, functioning underneath tight time and finances constraints, cannot explore the same options as the conceptual task.

“Luna is just a way of having type of all the most advanced matters and hoping to display you what the energy of the achievable is,” suggests Web page Motes, worldwide head of sustainability at Dell. “And then people will spin off to long run products.”