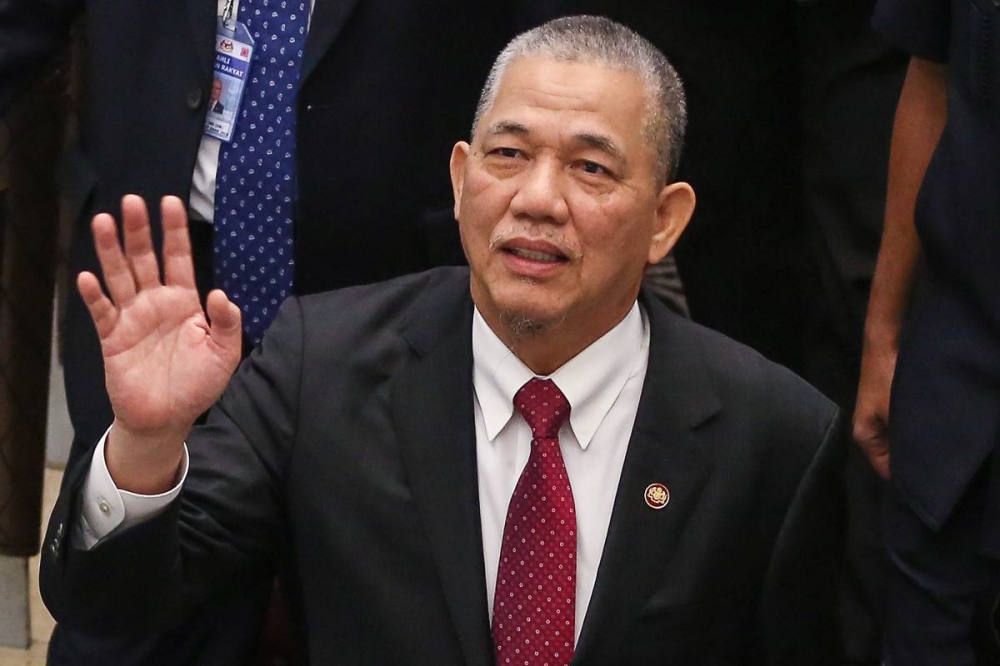

Palm oil industry must be ready to accept new technology changes, says DPM Fadillah

KUALA LUMPUR, Dec 20 — The palm oil industry should always be well prepared to embrace adjustments in conditions of new systems amid these difficult moments, Deputy Primary Minister Datuk Seri Fadillah Yusof explained.

He, who is also the minister of plantation and commodities, explained this included the adoption of the fourth industrial revolution (IR4.) thought and the usage of artificial intelligence (AI) and World-wide-web of issues (IoT) this kind of as digitalisation and automation technologies to boost the existing production procedures.

“The notion of smart palm oil mills based on zero discharge is the way of the palm oil industry and this can give a new dimension in the manufacturing sector, primarily in terms of performance and constant operational monitoring and person-helpful,” he claimed at the opening of the Nationwide Seminar on Oil Palm Milling, Refining, Setting and High quality 2022 (POMREQ 2022) listed here now.

His speech was browse by the ministry’s Secretary-Standard Datuk Zurinah Pawanteh.

He explained smart palm oil mills would be developed via the initiative of the Malaysian Palm Oil Board (MPOB) in collaboration with the business, which is Fusionex Team.

“With the development and desire for environmentally friendly solutions becoming the demand from customers of the global industry, I suggest that attempts to minimize the carbon footprint of palm products be emphasised.

“Malaysia is dedicated to attain web zero Greenhouse Gasoline (GHG) Emissions concentrate on as early as 2050,” he reported.

He reported the palm oil field has an crucial job in this effort, specially in raising biogas seize in palm oil mills.

“For that objective, MPOB has designed biogas capture know-how and cooperated with the field to expand the software of biogas.

“According to MPOB’s details, 135 oil palm factories have set up biogas systems as of 2021, which is 30 per cent of the whole current oil palm factories, when 15 factories are in the method of development and 130 factories are in the system of setting up for the set up of biogas programs,” he explained.

In that regard, Fadillah claimed he hoped that factories that do not still have a biogas technique would also boost their endeavours to do so.

In the meantime, he reported sludge palm oil or palm acid oil has also grow to be really well-known for the export market place not long ago, specially to European international locations as a uncooked materials for biofuel manufacturing.

“Low-high quality palm oil from palm oil mills should really be separated not only to enhance the all round high quality of palm oil but also to supply extra profits by exporting the sludge oil.

“The sludge oil can also be applied as a uncooked substance for the production of biodiesel and biojet for the aviation field and with this exertion, the excellent of palm oil can be enhanced and the difficulty of contaminants in refined palm oil can be addressed with each other by the field and the government utilizing the technological innovation that is obtainable,” he additional. — Bernama